CNC

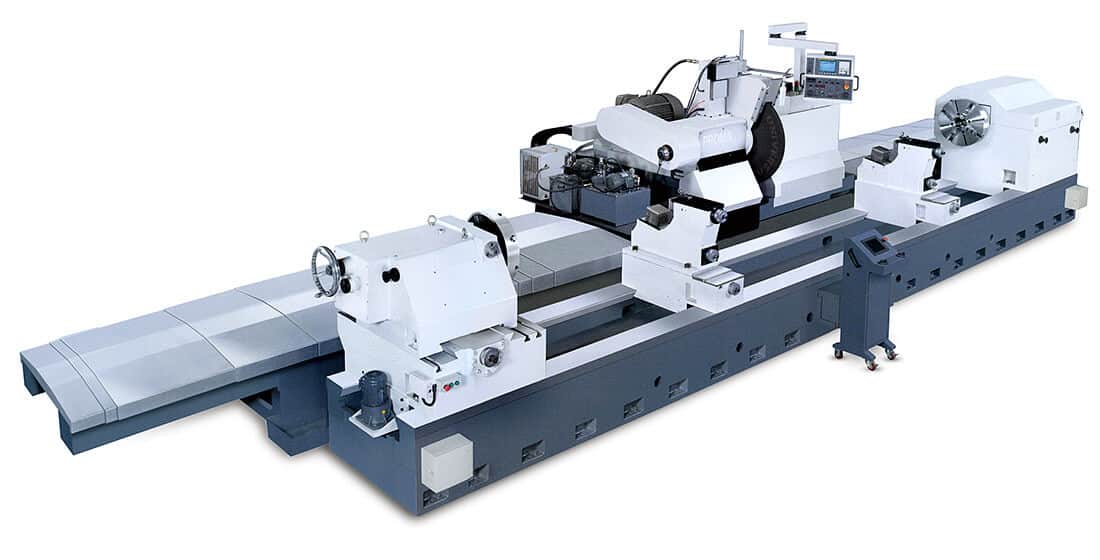

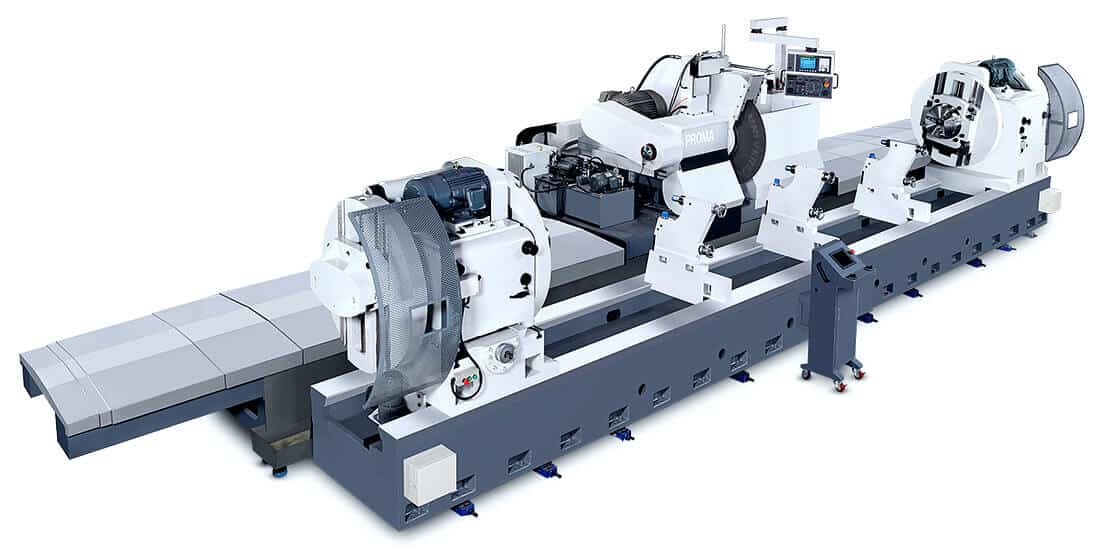

CNC Roll Grinder H Type 51″-79″ Swing

Description

The table, headstock, machine base, and carriage are all made of high strength FC-30~FC-35 castings. The guideways are constantly being lubricated by a hydrodynamic hydrostatic lubrication system to reduce drag between components and improve part finish.

MODELS AVAILABLEClick on Type for detail page |

|||||||

S Type |

M Type |

L Type |

H Type |

||||

| UNIT | S40 | M60 | L85 | L100 | H130 | H160 | H200 |

| Swing in mm | 400 | 600 | 850 | 1000 | 1300 | 1600 | Ø2000 |

PROMA CNC Roll Grinder H Type

The table, headstock, machine base, and carriage are all made of high strength FC-30~FC-35 castings. The guideways are constantly being lubricated by a hydrodynamic hydrostatic lubrication system to reduce drag between components and improve part finish.

The wheelhead spindle is designed with hydrodynamic bearing and is made of Ni-CR-Mo alloy for superior strength and maximum grinding finish.

The wheelhead and carriage are lubricated by a hydrodynamic hydrostatic lubrication system. The spindle and spindle motor utilize an indirect design to avoid strain on the motor.

The FANUC CNC-controller is used to develop the roll grinding process automatically. The system is configured with a humanized operation panel for the user which makes the grinding operation easy and precise. All the operator need to do is call a cutting program from memory to perform the grinding sequentially.

Crown grinding is also easy which include base arc curve SINE curve COSINE curve CVC curve and combined arc curve. The camber values is assigned by the program. The system has integrated a net function for output & input of the data for the cutting & the parameters of the machine and maintenance.

Tailstock re-positioning is made easy with the use of an air assist devise mounted on the bottom of the tailstock.

Work piece alignment is done via tailstock adjustment. The diamond wheel dresser is mounted on side of the tailstock for easy access. An optional revolving 4-jaw chuck tailstock is available for extremely heavy work pieces.

SPECIFICATION PAGE of all models

The Proma H Type comes in several configurations.

H-TYPE H85 H130 H160 H200

Max. swing over table Ø-850mm (33 inch) (Ø-1300mm (51 inch) Ø-1600mm 63 inch) Ø-2000mm (78 inch)

Max. distance between c.c.3M, 4M, 5M, 6M, 8M, 9M, 12M4M, 5M, 6M, 7M, 8M5M, 6M, 7M, 8M, 10M, 12M6M, 7M, 8M, 10M, 12M (118 inch to 40 ft).

Max. weight of workpiece 15,000kg 15,000kg 30,000kg 40,000kg

H40 400mm swing over table up to 8M between centers

HC Type Crankshaft Grinders

Having the same capability as larger grinders.

GENERAL BROCHURE

Get a Quote

H-Type cnc roll grinder

Distance between c.c. : 5M, 6M, 7M, 8M, 10M, 12M

Swing over table : Ø 1,300 Ø 1,600 Ø2,000 mm ( 51″ – 79″ )

Max weight of workpiece : 40,000kg

H-TYPE H130 H160 H200

Max. swing over table Ø 1300 mm Ø 1600 mm Ø 2000 mm ( 51″, 63″, 79″ )

Max. distance between c.c.4M, 5M, 6M, 7M, 8M5M, 6M, 7M, 8M, 10M, 12M6M, 7M, 8M, 10M, 12M

Max. weight of workpiece 15,000kg 30,000kg 40,000kg

Max. O.D. ground Ø1300mm Ø1600mm Ø2000mm

Range of grinding dia.Ø80 mm ~ Ø1300 mm Ø180 mm ~ Ø1600 mm Ø250 mm ~ Ø2000 mm

Online Brochure