Lathes CNC Oil Country SS Series 31″- 35″ Swing

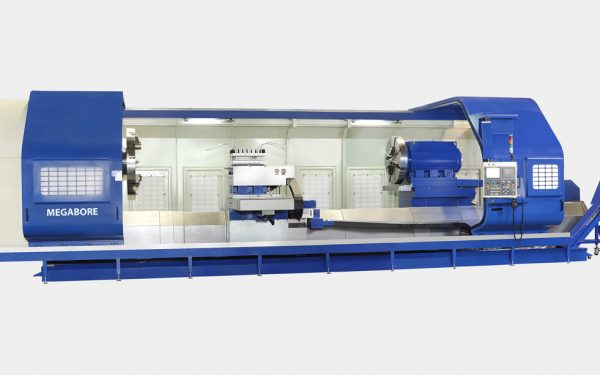

MEGABORE LG SERIES

LG Model

Lathes CNC Hollow Spindle LD Series

Lathes CNC Oil Country SS Series 31″- 35″ Swing

Description

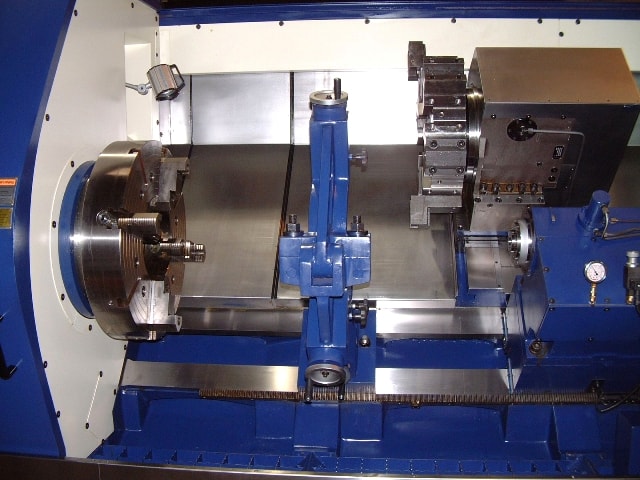

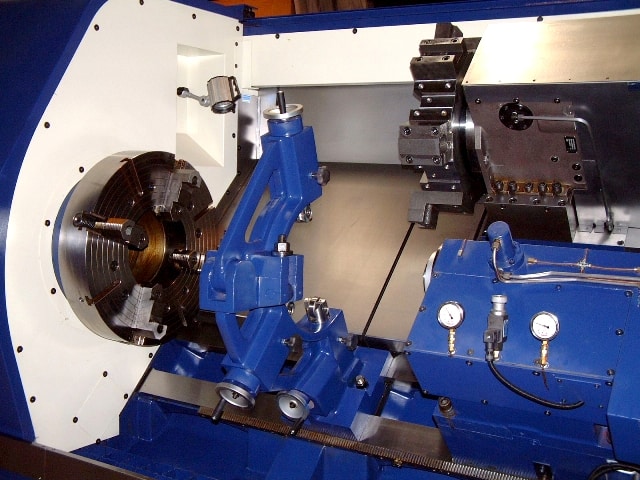

SS Series Slant Bed CNC

The SS series is our medium duty machine designed for those who prefer a slant bed machine to a flat bed or do not require our super heavy duty SA model. Available in 2 models SS-31 and SS-35, where the model number indicates swing in inches.

Megabore, oil country, slant bed lathe

| ITEM | UNIT | SS-31 | SS-35 | ||

| CAPACITY | |||||

| Centre height | mm (in.) | 505 (19.88) | 555 (21.85) | ||

| Swing over bed | mm (in.) | 750 (29.52) | 850 (33.46) | ||

| Swing over cross slide | mm (in.) | 670 (26.37) | 770 (30.31) | ||

| Distance between centres | mm (in.) | 700 (27), 1200 (47), 1700 (67), 2200 (86) 3200 (126), 4200 (166), 5200 (206) |

|||

| BED | |||||

| Width / Slant angle | mm (in.) / deg | 1145 (45.07) / 45° | |||

| CARRIAGE | |||||

| Width of cross slide | mm (in.) | 500 (19.68) | |||

| TURRET | |||||

| Standard tool post | Polygon Disc / VDI disc | ||||

| No. of tool stations | V12 / V8;V12 | ||||

| Turning Tool Size | mm (in.) | 32 x 32 (1.25) | |||

| Boring Tool Size(max.) | mm (in.) | 63 (2.5) | |||

| TRAVEL | |||||

| Cross slide(X axis) travel | mm (in.) | 420 (16.53) | |||

| Longitudinal(Z axis) travel | mm (in.) | 700 (27), 1200 (47), 1700 (67), 2200 (86) 3200 (126), 4200 (166), 5200 (206) |

|||

| Cutting feed rate | mm(in.)/rev | X axis : 0.001~250(0.00004~9.84) ; Z axis : 0.001~400(0.00004~15.75) | |||

| Rapid travel | M.(Ft.)/min | X axis : 6(19.68) ; Z axis : 6(19.68) | |||

| Ballscrew diameter | mm (in.) | X axis : 50(1.96) ; Z axis : 80(3.14) | |||

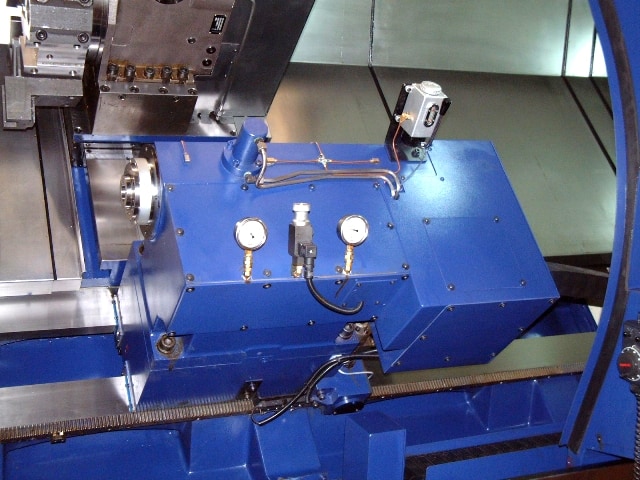

| TAILSTOCK | |||||

| Quill type | Built-in type, Rotating tailstock quill | ||||

| Quill diameter | mm (in.) | 160(6.29) | |||

| Quill travel | mm (in.) | 200(7.87) | |||

| Internal taper of quill | MT#5 | ||||

| MOTOR | |||||

| Headstock oil refrigerator | 18,000BTU(4,500Kcal) | ||||

| Main spindle | KW(HP) | 30/37(40/50)-STD. ; 37.5/45(50/60)-OPT. | |||

| Axis servo | KW(HP) | X axis : 7(9.387) ; Z axis : 7(9.387) | |||

| Hydraulic tank | KW(HP) | 3.7(5) | |||

| Coolant pump | KW(HP) | 1.05(1.4) | |||

| Controller | FANUC 0i-TF series-STD ; FANUC 31i-B series / Other required-OPT. | ||||

Note :

(1) X and Z axes actual cutting diameter will change when equipped with different turrets.

(2) Specifications are subject to change without notice for improvement