Lathe Heavy Duty PC Series 60″ – 80″ Swing

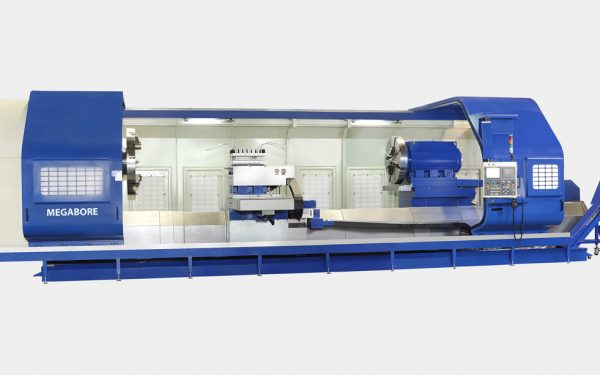

MEGABORE LG SERIES

LG Model

Lathes CNC Hollow Spindle LD Series

Lathe Heavy Duty PC Series 60″ – 80″ Swing

Description

The largest of the P Series when a large swing is required without the expense or size of a of a 3 shear bed.

PC-60 PC-70 PC-80 – (Model Number indicates swing over bed in inches).

Lathes Heavy Duty Megabore

ITEM |

UNIT |

PC-60 |

PC-70 |

PC-80 |

|

| CAPACITY | |||||

| Centre height | mm (in.) | 805 (31.69) | 930 (36.61) | 1055 (41.53) | |

| Swing over bed | mm (in.) | 1560 (61.41) | 1805 (71.06) | 2050 (80.70) | |

| Swing over cross slide | mm (in.) | 1100 (43.30) | 1350 (53.14) | 1600 (62.99) | |

| Swing over gap | mm (in.) | 2120 (83.46) | 2370 (93.30) | 2620 (103.14) | |

| Gap width from headstock(opt.) | mm (in.) | 600 (23.62) | |||

| Distance between centres | mm (in.) | 1500 (59.05), 2000 (78.74), 3000 (118.11), 4000 (157.48), 5000 (196.85), 6000 (236.22), 7000 (275.59), 8000 (314.96), 9000 (354.33), 10000 (393.70), 11000 (433.07), 12000 (472.44) |

|||

| BED | |||||

| Width (W/O auxiliary guide) | mm (in.) | 920 (36.22) | |||

| Width (W auxiliary guide) | mm (in.) | 1090 (42.91) | |||

| CARRIAGE | |||||

| Cross slide travel | mm (in.) | 1170 (46.06) | |||

| Compound tool post travel | mm (in.) | 600 (23.62) | |||

| 4-way tool post width | mm (in.) | 310 (12.20) | |||

| THREAD FEED RANGE | |||||

| Longitudinal feed | mm/rev (in.rev) | 0.045~2.55 (0.0018~0.1) | |||

| Cross feed | mm/rev (in.rev) | 0.023~1.28 (0.0009~0.05) | |||

| Longitudinal rapid feed | mm/rev (in.rev) | 2000 (78.74) | |||

| Cross rapid feed | mm/min (in/min) | 1270 (50.00) | |||

| Metric thread | mm (kinds) | 1~56 (60) | |||

| Inch thread | TPI (kinds) | 1/2~28 (60) | |||

| Module thread | MOD (kinds) | 0.25~14 (60) | |||

| Diamteral pitch thread | DP (kinds) | 2~112 (60) | |||

| Pitch of leadscrew | mm (TPI) | 12 (2) | |||

| TAILSTOCK | |||||

| Quill diameter | mm (in.) | 160 (6.29) | |||

| Quill travel | mm (in.) | 200 (7.87) | |||

| Inner taper of quill | MT#6 | ||||

| Bearing surface on the bed ways | mm (in.) | 760 (29.92) | |||

| MOTOR | |||||

| Main spindle motor | KW (HP) | 22(30)-STD. 29(40) / 37(50) / 44(60) / 55(75)-OPT. |

|||

| Coolant pump motor | KW (HP) | 0.1 (0.125) | |||

PC series |

PC-60 |

PC-70 |

PC-80 |

| Swing over bed | 1,560mm-(61.41″) | 1,805mm (71.06″) | 2,050mm (80.70″) |

| Swing over cross slide | 1,100mm-(43.30″) | 1,350mm (53.14″) | 1,600mm (62.99″) |

| Swing over bed gap | 2,120mm-(83.46″) | 2,370mm (93.30″) | 2,620mm (103.14″) |

| Distance between centers | 1,500mm (60″)-12,000mm (480″) in 40 increments | ||

| Spindle nose | A2-15—A2-40 | ||

| Spindle bore | 7″-30″ | 9″-32″ | |

| Spindle motor | Standard-20HP ; Option-40HP, 50HP, 60HP, 75HP | ||