Lathe CNC Heavy Duty KAN Series 80″ – 120″ Swing

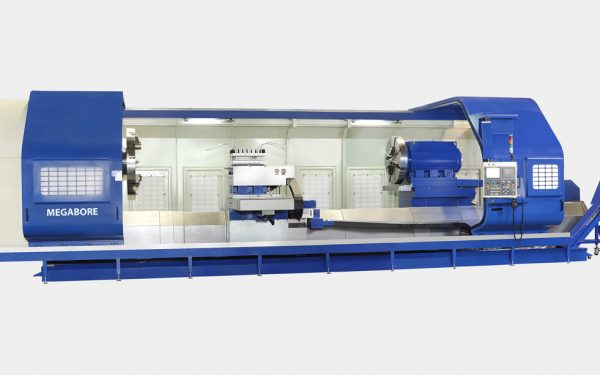

MEGABORE LG SERIES

LG Model

Lathes CNC Hollow Spindle LD Series

Lathe CNC Heavy Duty KAN Series 80″ – 120″ Swing

Description

KAN-50 KAN-60 KAN-70 KAN-80

Swing over bed 50, 60, 70, 80 inches.

3 shear bed Heavy Duty Flat Bed CNC Lathes

The latest in the product range from Megabore, the base machine can be configured in many ways to suit client requirements. Photos show some of the many configurations available.

Lathe CNC Heavy Duty KAN Series

KAN-80 KAN-90 KAN-70 KAN-100 KAN-120

Model number indicates swing in inches

| ITEM | UNIT | KAN-80 | KAN-90 | KAN-100 | KAN-120 |

| CAPACITY | |||||

| Centre height | mm (in.) | 1025 (40.35) | 1150 (45.27) | 1275 (50.19) | 1400 (55.11) |

| Swing over bed | mm (in.) | 2050 (80.7) | 2300 (90.55) | 2550 (100.39) | 2800 (110.23) |

| Swing over cross slide | mm (in.) | 1620 (63.77) | 1870 (73.62) | 2120 (83.46) | 2370 (93.3) |

| Distance between centres | mm (in.) | 3000 (118.11), 4000 (157.48), 5000 (196.85), 6000 (236.22),7000 (275.59), 8000 (314.96), 9000 (354.33), 10000 (393.70), 11000 (433.07), 12000 (472.44) |

|||

| BED | |||||

| Width | mm (in.) | 1350 (53.14) | |||

| CARRIAGE | |||||

| Width of cross slide | mm (in.) | 600 (23.62) | |||

| TURRET | |||||

| Standard tool post | Auto 4-way / Polygon Disc / VDI disc | ||||

| No. of tool stations | H4;H6 / V12 / V8;V12 | ||||

| Turning Tool Size | mm (in.) | 32 x 32 (1.25) | |||

| Boring Tool Size(max.) | mm (in.) | 63 (2.5) | |||

| TRAVEL | |||||

| Cross slide(X axis) travel | mm (in.) | 875 (34.44) | |||

| Longitudinal(Z axis) travel | mm (in.) | 3000 (118.11), 4000 (157.48), 5000 (196.85), 6000 (236.22),7000 (275.59), 8000 (314.96), 9000 (354.33), 10000 (393.70), 11000 (433.07), 12000 (472.44) |

|||

| Cutting feed rate | mm(in.)/rev | X axis : 0.001~250(0.00004~9.84) ; Z axis : 0.001~400(0.00004~15.75) | |||

| Rapid travel | M.(Ft.)/min | X axis : 6(19.68) ; Z axis : 6(19.68) | |||

| Ballscrew diameter | mm (in.) | X axis : 50(1.96) ; Z axis : 120(4.72) | |||

| TAILSTOCK | |||||

| Quill type | Built-in type, Rotating tailstock quill | ||||

| Quill diameter | mm (in.) | 235(9.25) | |||

| Quill travel | mm (in.) | 200(7.87) | |||

| Internal taper of quill | MT#6 | ||||

| MOTOR | |||||

| Headstock oil refrigerator | 18,000BTU(4,500Kcal) | ||||

| Main spindle | KW(HP) | 30/37(40/50)-STD. ; 37.5/45(50/60)-OPT. | |||

| Axis servo | KW(HP) | X axis : 7(9.387) ; Z axis : 7(9.387) | |||

| Hydraulic tank | KW(HP) | 3.7(5) | |||

| Coolant pump | KW(HP) | 1.05(1.4) | |||

| Controller | FANUC 0i-TF series-STD ; FANUC 31i-B series / Other required-OPT. | ||||

Note :

(1) X and Z axes actual cutting diameter will change when equipped with different turrets.

(2) Specifications are subject to change without notice for improvement